Corn Whiskey Clarity

Iowa’s spirited approach to permitting reform

Over the past two decades, Iowa has implemented several reforms aimed at enhancing the efficiency of its environmental permitting procedures. This report focuses on two key reforms at the state Department of Natural Resources (DNR): the adoption of business process improvement strategies, including Lean and Kaizen methodologies, to streamline operations; and the development and implementation of a new online permitting system called the Iowa Environmental Services Division Metrics dashboard.

These efforts have resulted in reductions in permit processing times, increased transparency, and improved customer service for permit applicants. The DNR’s Air Quality Bureau has been at the forefront of these reforms, with its first process improvement event held in 2003. Since then, the department has conducted numerous improvement events and adopted data-driven management practices to continuously enhance its permitting processes.

Performance improvement at Iowa DNR

In 2003, the Iowa Department of Management and the DNR Iowa began an initiative to improve environmental permitting processes. This initiative started after Iowa DNR was approached by leaders of the Iowa Coalition for Innovation and Growth, which is run by the Iowa Business Council, to discuss the burdensome process for obtaining pollution permits, specifically the Air Quality New Source Construction Permit, from DNR.

The Coalition for Innovation and Growth proposed that the state replicate a concept private sector companies had been implementing, called “Hot Teams.” These teams focus on improving key processes that are seen as barriers to business development and growth.

The initial focus was on construction permits. As part of this process, Iowa DNR held its first of several “kaizen improvement events” in June of 2003 (“kaizen” is a Japanese word meaning “change for better”). A kaizen event starts out with a clear mandate to improve a specific process to reduce waste and create efficiencies. The events then focus on immediate process improvement changes and actionable next steps to achieve the mandate. According to a representative from the DNR, “We believe it was the first process improvement event in state government.”

According to a 2011 summary produced by the state of Connecticut, Iowa’s early Lean efforts managed to reduce permit issue time frames from 214 days to 180 days for complex permits and from 62 days to six days for certain New Source Review (NSR) permits. The success of the event led to an official partnership between the state and Iowa business leaders. Since that initial kaizen event, improvement efforts have continued with over 400 sponsored events occurring across the executive branch.

Kaizen events, which are typically a week long, included programs related to Value Stream Mapping and Lean training. Value Stream Mapping is a process analysis strategy for helping businesses to visualize and improve steps in the delivery process of a product, and Lean is a process improvement methodology typically associated with manufacturing, but which has been adapted for more general process improvements in workplaces, including in state government. Kaizen events are often a key component of the Lean process.

DNR’s Lean-in approach to permitting reform

The term “Lean,” was coined by John Krafcik in his article “Triumph of the Lean Production System” and further popularized by James Womack and coauthors in the 1990 book, The Machine that Changed the World, both of which described the manufacturing paradigm established by Toyota.Iowa law codifies the definition of Lean as “a business-oriented system for organizing and managing product development, operations, suppliers, and customer relations to create precise customer value, expressed as providing goods and services with higher quality and fewer defects and errors, with less human effort, less space, less capital, and less time than more traditional systems.”

A state webpage describes the benefits of Lean as follows: “Lean courses promote a mindset of continuous improvement in order to make government services easier, faster, better and less costly. Courses provide training on Lean methodology and tools which assist in problem solving, removing inefficiencies and achieving results.” The Iowa Department of Management website offers a host of Lean tools and resources targeted at state employees. There is a noted emphasis on identifying the cause, or multiple causes, of problems and process breakdowns. For example:

“The 5 Whys” method recommends a series of questions to understand the layers of a problem, ultimately tracing the source of the problem back to its root cause.

The “5S Audit Checklist” (Sort, Set-In-Order, Shine, Standardize and Sustain) is a tool to measure and improve workspace organization to reduce waste. It is intended to quickly identify areas that need improvement and to evaluate workspaces to improve organization, safety, and ensure sustainability of results.

One Iowa DNR employee described how the process works this way: “Several years ago here in Iowa we went through a continuous improvement process for both minor NSR and major NSR permitting. It involved getting people from industry on workgroups to outline the steps in the permitting process and to reduce the steps along with setting goals for permitting time frames.” In a 2008 EPA report, process improvements at the Iowa DNR Air Division were credited to kaizen events and to their continuous Lean process improvement initiatives. Specific improvements in state permitting included:

- Creation of a dedicated a team to address the air permit backlog;

- Elimination of sixteen process steps (from 23 to 7);

- Reduction in permit handoffs (where responsibility shifts from one individual at the agency to another) from 18 to 4;

- Moving staff offices to facilitate better work flow;

- More complete air construction permit applications submitted; and

- Elimination of a 600 air construction permit backlog.

In response to the early successes of the Lean program, the Iowa legislature passed a bill in 2009 creating the Lean Enterprise Office within the Department of Management. The Iowa Lean Consortium was formed in 2010, of which the State of Iowa is a member. It merged in 2018 with Iowa State University’s Center for Industrial Research and Service. In the mid-2010s, Iowa, along with representatives from four other states, participated in an Environmental Protection Agency-organized workgroup to produce a Lean Starter Kit as a resource for other states. “Special recognition” was given to Iowa’s Department of Management in the final 2017 document.

Environmental Services Division Metrics dashboard

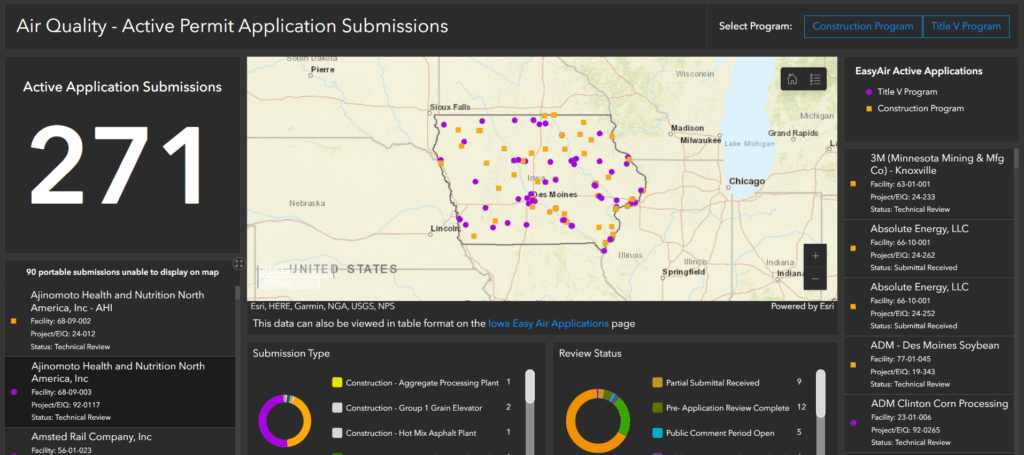

Iowa DNR also maintains an Environmental Services Division Metrics (ESDM) dashboard, to display data the agency collects on permits it is processing. The website includes data from the four bureaus within the environmental services side of the DNR. These are Land Quality, Field Services and Compliance, Water Quality and Air Quality. Each of these divisions utilizes the ESDM dashboard to oversee and manage various aspects of its permitting processes (see figure 2).

The Air Quality Bureau monitors air pollution from various sources and also includes greenhouse gases. It handles permits for construction and the operation of facilities that might affect air quality. The Field Services Bureau deals with inspections, complaints, and issues like open burning and dumping. The Land Quality Bureau manages programs for solid waste alternatives and flood mapping. The Water Quality Bureau oversees drinking water safety for community water systems.

Figure 2: Environmental Services Division Active Air Quality Permit Application submissions

The Iowa Electronic Application System for Air (Iowa EASY Air) portion of the ESDM dashboard is the final product of a years-long feedback gathering process involving both the Iowa legislature and Iowa DNR. The process began in 2014, when the Iowa legislature directed the agency to convene an Air Quality Stakeholder group to review and provide recommendations regarding the state’s Air Quality program. Recommendations were presented to the state Agriculture and Natural Resources Appropriations Subcommittee. In January 2016 the Air Quality Bureau began gathering additional input to develop new electronic permitting tools. The initial goal for deployment was 2017, but it was ultimately launched in December 2019.

Businesses wanting to build or expand must often apply for an air quality construction permit. Since there may be as few as one to as many as dozens of permits issued for a single project, the e-AirPermit system aims to simplify the application process, reduce paperwork, and expedite permit issuance for facilities subject to air quality regulations. The online portal allows applicants to submit applications for construction permits and air quality permits as well as utilize the State and Local Emissions Inventory System (SLEIS). SLEIS is a web-based emissions inventory reporting system used by firms to manage facility and equipment information and to report point source emissions data to DNR. It is described by the DNR as being “an intuitive reporting system that easily allows users to enter and extract data.”

Conclusion

Iowa DNR’s permitting reform efforts demonstrate a sustained commitment to improving both regulatory efficiency and service delivery. The agency’s adoption of business process improvement methodologies and its investment in technology solutions have yielded tangible results in faster permit processing times and increased transparency.

The data presented in this report show clear improvements across multiple permitting processes at the Iowa DNR following the implementation of Lean methodologies and other reforms. Processing times for various permits, including air quality, water, and land use permits, saw significant reductions – in some cases from months or even years down to just days or weeks. These efficiency gains were accompanied by process simplifications, such as reducing the number of steps and handoffs involved in permit reviews. The creation of dedicated teams and the reorganization of office spaces further contributed to streamlining operations.

To this day, DNR continues to regularly review and update its permitting processes based on stakeholder feedback and performance data. It continues to invest in staff training to ensure full utilization of new technologies and to identify needed process improvements. The DNR should continue to explore opportunities to extend similar reforms to new areas within the agency, as well as to share its experiences with additional departments across state government. Iowa DNR’s demonstrated commitment to environmental permitting efficiency provides valuable lessons for other states interested in permitting reform.